Scaffolding

[OHS General Regs., S. x] Follow these links

to related legislation.

Highlighted words reveal

definitions and supplementary

information when selected.

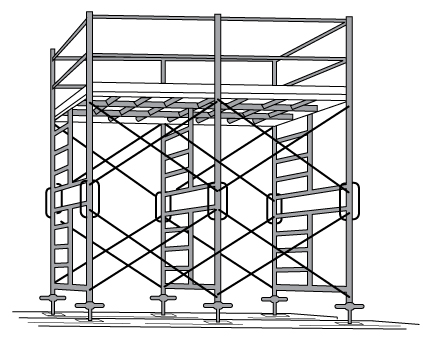

Although scaffolding can provide an efficient and safe way to perform work at heights, many incidents happen because scaffolds are improperly used or installed. Scaffolding consists of a temporary elevated platform that is used to support materials and employees while they work at heights. Falls from heights, and improper construction and use of scaffolds can result in injuries ranging from sprains to death.

General Responsibilities for Employers and Workers

Employers are responsible for making sure that all scaffolds meet the legal requirements. They are also responsible for making sure workers follow all safety procedures and that all provided equipment is used safely and properly. [Scaffolding Regs., S. 2]

Workers are responsible for:

- actively participating in all training;

- following all procedures related to safely constructing, using, maintaining and dismantling all types of scaffolds; and

- using all provided personal protective equipment safely and according to any instructions or training.

Self-employed people must follow the same scaffolding safety requirements. [Scaffolding Regs., S. 1 (3)]

Basic Scaffold and Work Platform Requirements

All employers must have the design specifications for their scaffolds on site, and available if there is an inspection. For a manufactured scaffold, keep the manufacturer’s instructions. For a scaffold designed by a professional engineer, keep the certified designs. Keep this documentation throughout the scaffold’s construction, use, and while it is being dismantled. [Scaffolding Regs., S. 2]

In general:

- Always inspect a scaffold before use. If a scaffold that is determined to be unsafe when inspection, do not use until it is repaired. [Scaffolding Regs., S. 7]

- Do not load scaffolds beyond its rated weight capacity. [Scaffolding Regs., S. 2]

- Do not use scaffolds in bad weather creating a hazardous situation. [Scaffolding Regs., S. 10]

- Do not allow workers to climb in between work platforms on the outside of scaffold frame. [Scaffolding Regs., S. 11 (3)]

Make sure scaffolds:

- are designed, constructed and maintained so that it can carry four times its likely maximum load; [Scaffolding Regs., S. 6]

- are built and dismantled with the supervision of a competent person; [Scaffolding Regs., S. 7 (4)]

- have a safe way for workers to access and leave the scaffold; [Scaffolding Regs., S. 6]

- are made of components and fitted with gear that meet the manufacturer's specifications or professional engineer's certification; [Scaffolding Regs., S. 6]

- if made of metal, are built, used, maintained and dismantled according to the manufacturer's specifications, or a professional engineer's design instructions; [Scaffolding Regs., S. 5]

- are inspected by a competent person each day before they are used and after any modification or repairs are made that may affect its strength. Inspectors must report their findings to the employer; [Scaffolding Regs., S. 7 (1), (2)]

- that are free standing and at least three times higher than its minimum base dimension, have guy wires or outrigger stabilizers that prevent tipping or another equally safe means of support; and[Scaffolding Regs., S. 10 (4)]

- are erected without coming within the limits of approach to electrical wires. [OHS General Regs., S. 36.20]

| Normal Phase to Phase Voltage of Live Power Line |

Minimum Distance |

|---|---|

| Up to 750 volts | 900 mm (3 ft.) |

| 751 – 100,000 volts | 3600 mm (12 ft.) |

| 100,001 – 250,000 volts | 5200 mm (17 ft.) |

| 250,001 – 345,000 volts | 6100 mm (20 ft.) |

Make sure the workplace platform is constructed so that there is a complete guardrail surrounding the work area. A complete guardrail includes a top rail, a middle rail and a toe board.

Make sure work platforms, are designed, constructed and maintained so that it can carry four times its likely maximum load. They must also be securely fastened in place by cleating, wiring or another method providing equal safety and prevention of shifting or other movement. Platform specifications are outlined in the regulations. [Scaffolding Regs., S. 10]

Work platforms up to 9m

When a scaffold’s only access is to a work platform is 9 m or less above the ground, make sure there is access by a vertical ladder, portable ladder, stairway, or use end frames to provide a ladder-like structure having horizontal members uniformly spaced at 30 cm. [Scaffolding Regs., S. 11 (1)]

Work platforms over 9m

When a scaffold’s only access is to a work platform is over 9 m above the ground, provide a stairway that reaches the ground, an attached vertical ladder, with guarded rest platforms at least every 9 m or use end frames that provide a ladder-like structure having horizontal members uniformly spaced at 30 cm on centre with guarded rest platforms at least every 9 m. [Scaffolding Regs., S. 11 (2)]

Scaffolds Constructed from Ground or Safe Surface

Scaffolds erected from the ground or other safe surfaces, must be: [Scaffolding Regs., S. 4]

- constructed by a competent person;

- plumb and level;

- made with vertical supports that rest on a firm footing and able to support its maximum load without any deformation or shifting that could compromise its safety. If there is no firm footing, rest on mud sills that prevent unsafe settlement, deformation or tipping;

- have all their parts fastened and secured together in order to prevent lateral movement and have at least one tie for each 4.6 m vertical interval, and 6.4 m. horizontal interval, and have diagonal braces that run both vertically and horizontally;

- made of vertical supports and bearers no more than 3 m apart; and

- secured against lateral movement where the scaffold is enclosed.

Protection from Falling Objects

The employer is also responsible for providing overhead protection to all those who may access the area on or under the scaffold. Tie tools, materials or equipment to the scaffold or use some method that will prevent objects from falling. [Scaffolding Regs., S. 9] Do not move a scaffold without tying or securing objects. [Scaffolding Regs., S. 10]

When constructing, dismantling or moving a scaffold, make sure everyone performing the work on the scaffold uses a fall arrest system. [Scaffolding Regs., S. 9]

Rolling scaffolds

Do not move a rolling scaffold on an inclined surface unless adequate precautions are taken to prevent tipping, sliding, rolling away, and any other dangerous or sudden movements.

Rolling scaffolds must: [Scaffolding Regs., S. 12]

- have working brakes and locking devices to prevent movement;

- have a mechanism to secure the wheels of the scaffold;

- have diagonal bracing in the vertical place, at every level and on each side, and in the horizontal plane, at every 4.6m; and

- be made of parts that are designed by a manufacturer or a professional engineer and are securely fastened with locking devices that are designed for use on a rolling scaffold.

Pumpjack scaffold – compliance

Pumpjack scaffolds are for light duty only. Only two workers may be on a pumpjack scaffold at a time. [Scaffolding Regs., S. 13 (4)] Metal pumpjack scaffolds cannot be more than 13.7 m in height; and must be braced every 4.6 m. [Scaffolding Regs., S. 13 (1)] Pumpjack scaffolds with supports made of wood must not be more than 7.3 m in height and must be braced every 3 m. [Scaffolding Regs., S. 13 (2)]

- Make sure that there is a guardrail system at the ends of the pumpjack scaffold.

- Make sure that the manufacturer’s specifications are on site before erecting a pumpjack scaffold.

Suspended Scaffolds

For suspended scaffold (that is commercially manufactured), the employer must make sure it is erected, used, maintained, and dismantled according to the manufacturer’s specifications. [Scaffolding Regs., S. 19 (9)] For suspended scaffold, employers must develop written procedures for its operation. The scaffold must be designed, constructed, erected, used, operated, maintained, monitored and dismantled according to CSA Standard Z91-02 Health and Safety Code for suspended equipment operations as amended.

Manually operated suspended scaffold have a secondary locking device for the hoisting mechanism that can be securely locked in a positive drive position.

Do not use outriggers made of wood or wooden parts.

When using suspended scaffolds, they must: [Scaffolding Regs., S. 14]

- be suspended by at least two upper attachments making the suspension ropes parallel (except if the suspended scaffold is a boatswain's chair);

- be tied, during use to an outrigger or to a parapet clamp (if it is impractical to tie the scaffold to an outrigger);

- be lowered to the ground or lashed to the attached building or structure, if it is not being used;

- not be moved up or down when it is being used, if the work platform is more than 10% out of level;

- have a controlled descent device (other than a lifeline), if there is no exit for workers during a mechanical or power failure;

- have at least two independent means of support to prevent the collapse of an upper platform tiered on one suspended scaffold;

- have solid counterweights that are securely attached to the outriggers and able to counterbalance four times the rated capacity of the scaffold;

- have a positive stop device on the outer end of the outrigger to prevent the movement of the rope if the outrigger does not have an eye bolt;

- have the maximum allowable printed on each component or otherwise accessible to the worker at the work area where the outrigger is locate;.

- prevent movement of the outrigger or parapet clamp by tying it to an anchor point;

- fasten components of outriggers with two independent fastening systems to prevent its parts from separating;

- have ropes (if it is made with ropes) able to carry ten times the expected maximum load. Wire ropes must be at least 7.8 mm in diameter. Polypropylene ropes must be at least 16 mm in diameter;

- have ropes extend to the nearest safe surface and be secured so they do not tangle or foul if a suspended scaffold can be moved upward and downward;

- use a fall arrest system with a ropegrab and an independent life line while entering, leaving or working on a suspended scaffold;

- be roped off or barricade the area beneath a suspended scaffold or provide overhead protection to workers below. Post warning signs to notify workers of the overhead hazard; and

- protect suspension lines, tiebacks, lifelines and other supporting components made of rope and the internal hoist mechanisms from abrasions, corrosive substances, other foreign materials, heat or work activities that might cause damage.

Power units on suspended scaffold must have positive pressure controls and positive drives, for raising and lowering the work platform. [Scaffolding Regs., S. 14 (9)]

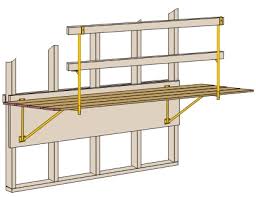

Bracket scaffolds cannot have brackets more than 3 m apart and they must be securely attached to the structural wall to prevent dislodging. [Scaffolding Regs., S. 15]

Roofing brackets must be securely nailed to the roof and have a span of no more than 3 m. [Scaffolding Regs., S. 16]

Bracket scaffolds and roofing brackets are not considered a form of fall protection unless stated in the manufacturer’s specifications.

Industrial Lift Trucks and platforms

An employer may use a fork-lift platform if it: [Scaffolding Regs., S. 17]

- is erected, used, maintained and dismantled according to the manufacturer’s or professional engineer’s specifications;

- has guardrails;

- is securely attached to a lift truck during use;

- is operated at all times by a competent person, who is always at the controls; and

- is used only on a firm, flat surface that is stable.

If a fork-lift platform is elevated, and a worker is on the platform, the truck may not be moved horizontally. [Scaffolding Regs., S. 17(5)]

Lift trucks may not be used to lift a fork-lift platform if the ground or other conditions affect the stability of the truck, or if the truck may tip, displace or be unstable. [Scaffolding Regs., S. 17(1)] The lift truck must comply with CSA Standard B335-15 Safety standard for lift trucks.

Cantilevered scaffold - outrigger requirement

Cantilevered scaffolds must have a fully decked work platform. To use cantilevered scaffolds as a landing platform for loads deposited by a crane or hoist, provide workers with fall protection and install a guardrail at the entrance to the work platform it is not in use. [Scaffolding Regs., S. 18]

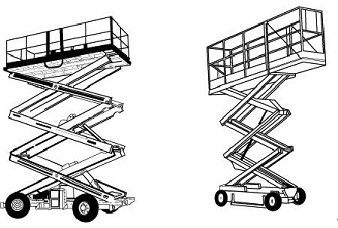

Power operated elevating work platform

Power operated elevating work platform must have: [Scaffolding Regs., S. 19]

- a competent operator;

- an emergency stop button;

- positive pressure controls for the positioning of the work platform;

- a power elevating mechanism equipped with positive drives for both raising and lowering the work platform;

- an interlock device that limits lateral movement when the height of the work platform exceeds that specified by the manufacturer;

- an elevating mechanism that locks the work platform in the elevated position during a failure;

- a way for the platform’s operator and the worker on it to communicate directly; and

- on the platform, there must be copies of:

- the operator's manual;

- applicable operational limitations and requirements, including those relating to the use of outriggers, stabilizers and extendable axles;

- the specific surface conditions required for safe use in the elevated position;

- the manufacturer’s warnings;

- the name and number of the relevant CSA Standard; and

- the name and address of the owner of the work platform.

- posted at the controls of the work platform, its rated capacity and the direction of the machine movement for each operating control of the work platform (except for a boom-type elevating work platform).

Equipment owners and employers providing a power operated elevating work platform, must make sure it meets specified CSA standards and has been maintained according to the standard’s requirements. [Scaffolding Regs., S. 19(4)]

Workers operating a power operated elevating work platform must be given received oral or written instructions on how to safely operate the provided work platform or be adequately trained to operate it. [Scaffolding Regs., S. 19 (9)] Required training by a competent person must include instruction on:

- the manufacturer's specifications;

- all relevant load limitations; and

- the kind of surfaces on which the power operated elevating work platform are designed to be used.

Training must also include a hands-on demonstration, showing the proper way to use all the platform’s controls. The employer should maintain all documentation that proves operator competency.

The power operated elevating work platform’s owner must keep a permanent record of all inspections, tests, repairs, modifications and maintenance performed on it. The records must include the name and signature of the person who performed the inspection, test, repair, modification or maintenance.

Further requirements include:

- When working on or moving a power operated elevating work platform use a fall arrest system that complies with the Fall Protection Regulations. [Scaffolding Regs., S. 19 (12)]

- Remove workers from a failing power operated elevating work platform before it is lowered or any repairs are made. [Scaffolding Regs., S. 19 (2)]

- Do not load a platform over its rated capacity.

- Do not load the platform in a way that it could become unstable or create a hazardous situation.

- Make sure a power operated elevating work platform is on a firm, level surface, unless the manufacturer specifies other surfaces it on which it is able to be used.

- Follow all of manufacturer's specifications of power operated elevating work platform.

Crane or Hoist Suspended Work Platforms

Do not work from a crane supported work platform unless the job cannot be done safely on a scaffold in a safe or a scaffold is prohibitively impractical. [Scaffolding Regs., S. 20]

A crane or hoist used to suspend the work platform must be: [Scaffolding Regs., S. 20(3)]

- operational in the power up and power down positions;

- equipped with an automatic brake system that operates when the crane or hoist is not lifting or lowering;

- equipped with an anti-two block device;

- be operated at a safe lifting and lowering speed; and

- able to have at least three full wraps on the hoisting drum at all times.

When workers are on a crane supported work platform, the crane operator must have a means to communicate with them at all times.

Make sure a second support is shackled above the ball of the crane that can support a crane supported work platform with workers on it if the primary supports fail.

Make sure workers on a crane supported work platform use a fall arrest system attached to an anchor point on the work platform. [Scaffolding Regs., S. 20(8)]

Only lift workers in equipment designed to carry people. [Scaffolding Regs., S. 21]

A scaffold must be certified by a professional engineer if:

- It is a pumpjack scaffold taller than 9.75 m with at least one supporting member that is not commercially manufactured.

- It is a wooden scaffold taller than 9.75 m.

- It is a suspended scaffold with at least one supporting member that is not commercially manufactured, two linked or tiered work platforms or 15 m above its foundation.

- It is a crane with at least one supporting member that is not commercially manufactured.

- It is a fork-lift platform with at least one supporting member that is not commercially manufactured.

- An officer determines that wind, elevation or other unique conditions, requires a professional engineer's certified design to ensure the adequacy of the scaffold at the workplace.

General Regulations

EC180/87

Part 36 ELECTRICITY

Section 36.20 Distances from energized conductors

36.20 The employer shall ensure that, subject to sections 36.16 and 36.22, and except for electrical utilities, a worker shall not carry out any work which is liable to bring any person or apparatus, machine, machine component, material or property within a distance of energized electrical conductors closer than as specified in the following table:

Table

| Nominal Phase to Phase Voltage of Live Power Line | Minimum Distance |

| Up to 750 volts | 900 mm (3 ft.) |

| 751 - 100,000 volts | 3 600 mm (12 ft.) |

| 100,001 - 250,000 volts | 5 200 mm (17 ft.) |

| 250,001 - 345,000 volts | 6 100 mm (20 ft.) |

[EC2021-126, s. 3]

Scaffolding Regulations

EC2006-44

Section 1 Definitions

1. (1) In these regulations

(a) "Act" means the Occupational Health and Safety Act ;

(b) "boatswain's chair" means a seat attached to a suspended rope, designed to accommodate one person in a sitting position;

(c) "bracket scaffold" means a scaffold consisting of a work platform supported by brackets attached to a structural wall;

(d) "cantilevered scaffold" means a scaffold consisting of a work platform attached to components that extend out from a building or a structure;

(e) "competent person" means a person who is

(i) qualified because of that person's knowledge, training and experience to do the assigned work in a manner that will ensure the health and safety of persons in the workplace, and

(ii) knowledgeable about the provisions of the Act and the regulations that apply to the assigned work, and about potential or actual danger to health or safety associated with the assigned work;

(f) "crane supported work platform" means a work platform suspended from the cable of a hoist or crane;

(g) "fork-lift platform" means a work platform supported by an industrial lift truck;

(h) "ladderjack scaffold" means a scaffold consisting of a work platform supported by one or more brackets that are attached to one or more ladders;

(i) "light duty scaffold" means a scaffold designed to support a uniformly distributed load of not more than 366 kg/m2;

(j) "power operated elevating work platform" means a work platform elevated and lowered by means of a mechanical, hydraulic, pneumatic or other powered mechanism;

(k) "professional engineer" means a person who may, under the Engineering Profession Act R.S.P.E.I. Cap. E-8.1, engage in the practice of engineering;

(l) "pumpjack scaffold" means a scaffold consisting of a work platform supported by vertical poles and adjustable support brackets;

(m) "rated capacity" means, in respect of a scaffold, the maximum safe working load for the scaffold

(i) as determined by the manufacturer of the scaffold, if the scaffold is a manufactured scaffold, or

(ii) as certified by a professional engineer;

(n) "rolling scaffold" means a scaffold consisting of a work platform that is

(i) supported by wheels, and

(ii) designed to be moved manually;

(o) "roofing bracket" means a bracket

(i) that is secured to a sloped roof, and

(ii) to which a work platform is secured;

(p) "safe surface" means a surface at a workplace that

(i) has sufficient size and strength to adequately support a worker who falls on to the surface, and

(ii) is sufficiently horizontal to prevent a further fall from the surface by a worker who has fallen on to the surface;

(q) "scaffold" means any temporary work platform and its supporting structure that is used to support workers and materials;

(r) "suspended scaffold" means a scaffold with a work platform suspended from and supported by components cantilevered out from a building or other structure, and includes a swingstage, a boatswain's chair and a multi-point suspended scaffold;

(s) "swingstage" means a scaffold with a work platform supported by suspension ropes that are parallel;

(t) "wooden carpenter's portable bracket scaffold" means a scaffold consisting of a work platform supported by a triangular wooden bracket attached to a structural wall which does not normally have another means of support;

(u) "work area" means a location at the workplace at which a worker is, or may be required or permitted to be, stationed and includes a work platform;

(v) "work platform" means a temporary horizontal working surface that provides access to a work area and support to a worker at the work area.

(2) Where there is an inconsistency between a provision of these regulations and a standard or a manufacturer's specification incorporated by reference in these regulations, the provision of these regulations prevails to the extent of the inconsistency.

(3) A duty or requirement that is imposed on an employer or a worker under these regulations applies to a self-employed person, with such modifications as the circumstances require.

Section 2 Scaffold requirements

2. (1) An employer shall ensure that a scaffold provided to a worker by the employer for the use of a worker

(a) is not loaded in excess of its rated capacity;

(b) is not erected, operated, used, dismantled or supplied at a workplace unless the employer has available for inspection at the workplace, the design specifications for the scaffold

(i) provided by its manufacturer, if the scaffold is a manufactured scaffold, or

(ii) certified by the professional engineer who certified the design of the scaffold pursuant to section 8; and

(c) is not used to support a ladder or other structure or device for the purpose of increasing the working height of the ladder, or other structure or device.

(2) No employer shall provide for the use of a worker, and no worker shall use, a ladderjack scaffold or a wooden carpenter's portable bracket scaffold.

Section 4 Scaffolds - erected from ground or safe surface

4. Where an employer provides, for the use of a worker, a scaffold that is erected from the ground or other safe surface, the employer shall ensure that the scaffold

(a) is erected plumb and level;

(b) is constructed with vertical supports that

(i) rest on a firm footing that can support the maximum load of the scaffold without unsafe settlement or deformation, or

(ii) where there is no firm footing, rest on mud sills that prevent unsafe settlement, deformation or tipping;

(c) is constructed of components that are secured to prevent lateral movement and

(i) has at least one tie for each

(A) 4.6 m vertical interval, and

(B) 6.4 m horizontal interval, and

(ii) has diagonal braces in both the vertical and horizontal planes of the scaffold;

(d) is installed and constructed by a competent person to secure the scaffold against lateral movement where the scaffold is enclosed; and

(e) is constructed of vertical supports and bearers that are no greater than 3 m apart.

Section 5 Metal scaffolds

5. An employer shall ensure that a metal scaffold provided by the employer for the use of a worker

(a) is erected, used, maintained and dismantled in accordance with the manufacturer's specifications, or in accordance with a professional engineer's design that includes instructions on erection, use, maintenance and dismantlement;

(b) notwithstanding clause 4(c), is braced diagonally in the vertical plane, at every level and on each side, and in the horizontal plane, at every 4.6 m;

(c) has components that are securely fastened with locking mechanisms, as designed by the manufacturer or a professional engineer, both during erection and otherwise; and

(d) is equipped with screwjacks where necessary to ensure that the scaffold is plumb and level.

Section 6 Scaffold requirements

6. An employer shall ensure that every scaffold provided by the employer for the use of a worker

(a) is capable of supporting at least four times the maximum load likely to be imposed;

(b) has a safe means of access and egress; and

(c) is provided with fittings and gear that comply with the manufacturer's specifications or a professional engineer's certification.

Section 7 Inspection by competent person

7. (1) An employer shall ensure that every scaffold provided by the employer for the use of a worker is inspected by a competent person each day prior to use, and after any modification, for any defect, damage, deterioration or loosening that may affect its strength.

(2) A person who inspects a scaffold pursuant to subsection (1) and who finds any defect, damage, deterioration or loosening referred to in that subsection shall report the finding to the employer for whom the inspection is made.

(3) On receipt of a report concerning a scaffold made pursuant to subsection (2), an employer shall ensure that the scaffold is not used until it is repaired.

(4) An employer shall ensure the erection and dismantling of every scaffold provided by the employer for the use of a worker is supervised by a competent person.

Section 9 Protection from falling objects

9. Where work for an employer is being performed

(a) on a scaffold provided by the employer or by another employer; and

(b) above a work area to which access is not restricted, the employer providing the scaffold shall ensure that any workers having access to the work area are protected from the hazard of objects falling from the scaffold by

(c) providing overhead protection;

(d) having any tool, material or equipment on the scaffold tied to the scaffold; or

(e) employing such other means that provide an equivalent level of safety to the provision of overhead protection.

Section 10 Scaffold stability and movement

10. (1) Where a worker is working for an employer from a scaffold provided by the employer or by another employer, the employer providing the scaffold shall ensure that the scaffold is not moved horizontally while the worker is on the scaffold, unless the worker is protected against falling by a fall arrest system that complies with the Fall Protection Regulations (EC633/04).

(2) An employer who provides a scaffold for the use of a worker shall ensure that the scaffold is not moved horizontally while any unsecured tool, material or equipment is on the scaffold.

(3) Where an employer causes a scaffold to be erected or dismantled, the employer shall ensure that, during the erection or dismantling of the scaffold, no worker works from the scaffold unless

(a) the work platform of the scaffold is designed and constructed or erected in accordance with the requirements of these regulations; or

(b) the worker performing the work is protected by a means of fall protection that complies with the Fall Protection Regulations (EC 633/04).

(4) Where a free standing scaffold that is at least three times higher than its minimum base dimension is provided by an employer for the use of a worker, the employer shall ensure that the scaffold is equipped with

(a) guy wires or outrigger stabilizers that prevent tipping; or

(b) such other means of support that provides an equivalent level of safety.

(5) An employer shall ensure that a scaffold is not used by a worker when there is a severe weather condition which may create a hazardous situation.

Section 11 Access to scaffolds - up to 9 m

11. (1) An employer who provides a scaffold for the use of a worker shall ensure that access to otherwise inaccessible work platforms of the scaffold, that are up to 9 m above the ground or other safe surface, is provided by

(a) end frames providing a ladder-like structure having horizontal members uniformly spaced at 30 cm on centre, or

(b) a vertical or portable ladder, or stairway, attached to the scaffold.

(2) An employer who provides a scaffold for the use of a worker shall ensure that access to otherwise inaccessible work platforms of the scaffold, that are over 9 m above the ground or other safe surface, if any, is provided by

(a) a stairway erected for the full height of the scaffold,

(b) an attached vertical ladder, with rest platforms at least every 9 m which are fully guarded except at the ladder location, or

(c) end frames providing a ladder-like structure having horizontal members uniformly spaced at 30 cm on centre, and rest platforms at least every 9 m which are fully guarded except at the ladder location.

(3) No employer who provides a scaffold for the use of a worker shall allow the worker to climb the outside of scaffold frames between work platforms.

Section 12 Rolling scaffolds

12. (1) An employer who provides a rolling scaffold for the use of a worker shall ensure that the rolling scaffold

(a) is equipped with

(i) working braking and locking devices that prevent movement of the scaffold, and

(ii) a mechanism that, when applied, secures the wheels of the scaffold; and

(b) is assembled

(i) with diagonal bracing in the vertical place, at every level and on each side, and in the horizontal plane, at every 4.6m, and

(ii) from components that

(A) are designed by a manufacturer or a professional engineer, and

(B) are securely fastened with locking devices, as designed by the manufacturer or a professional engineer for use with the components of the rolling scaffold.

(2) An employer who provides a rolling scaffold for the use of a worker shall ensure that the braking and locking devices and the securing mechanism referred to subsection (1) are applied prior to and while a worker is using the scaffold.

(3) An employer who provides a rolling scaffold for the use of a worker shall ensure that the rolling scaffold is not moved by a worker on an inclined surface unless adequate precautions are taken to prevent tipping, sliding, acceleration or any other dangerous or sudden movement.

Section 13 Pumpjack scaffold - compliance

13. (1) An employer who provides a pumpjack scaffold for the use of a worker shall ensure that the pumpjack scaffold complies with this section.

(2) A pumpjack scaffold made of metal

(a) shall not be more than 13.7 m in height; and

(b) shall be braced every 4.6 m, starting at the base of the scaffold.

(3) A pumpjack scaffold that includes one or more supports made of wood

(a) shall not be more than 7.3 m in height; and

(b) shall be braced every 3 m, starting at the base of the scaffold.

(4) An employer who provides a pumpjack scaffold for the use of a worker shall ensure that a pumpjack scaffold

(a) is used only as a light duty scaffold; and

(b) is not used by more than two workers at one time.

(5) An employer who provides a pumpjack scaffold for the use of a worker shall ensure that a pumpjack scaffold is erected, used, maintained and dismantled

(a) according to the manufacturer's specifications; or

(b) in accordance with a professional engineer's design that includes instructions on erection, use, maintenance and dismantlement.

Section 14 Suspended scaffolds - commercially manufactured

14. (1) Where a suspended scaffold that is commercially manufactured is provided by an employer for the use of a worker, the employer shall ensure it is erected, used, maintained and dismantled in accordance with the manufacturer's specifications.

(2) Where a suspended scaffold that is not commercially manufactured is provided by an employer for the use of a worker, the employer shall

(a) develop written procedures for its operation; and

(b) ensure that the suspended scaffold is

(i) operated in accordance with written operating procedures developed by the employer under clause (a);

(ii) constructed, erected, used, operated, maintained and dismantled in accordance with a professional engineer's design that includes instructions on erection, use, maintenance and dismantlement; and

(iii) designed, constructed, erected, used, operated, maintained, inspected, monitored and dismantled in accordance with CSA Standard Z91-02 , "Health and Safety Code for suspended equipment operations", as amended from time to time.

(3) An employer shall ensure that a suspended scaffold provided by the employer to a worker is suspended by at least two upper attachments that are placed so that the suspension ropes are parallel, unless the suspended scaffold is a boatswain's chair.

(4) An employer shall ensure that a suspended scaffold provided to a worker is tied, during use,

(a) to an outrigger; or

(b) to a parapet clamp, where it is impractical to tie the scaffold to an outrigger.

(5) An employer shall ensure that a suspended scaffold provided by the employer to a worker is

(a) lowered to the ground; or

(b) lashed to the building or other structure to which it is attached,

when the scaffold is not in use.

(6) An employer shall ensure that a suspended scaffold provided by the employer to a worker is not moved up or down by a worker during use if the work platform of the scaffold is more than 10% out of level.

(7) Where a powered suspended scaffold is provided by an employer to a worker and the employer does not otherwise provide a safe means of egress to the powered suspended scaffold, the employer shall ensure that the powered suspended scaffold is equipped with a controlled descent device, other than a lifeline, for use in the event of a mechanical or power failure, that can

(a) be safely operated from the work platform; and

(b) move the scaffold to a point of safe egress.

(8) An employer shall ensure that a suspended scaffold provided by the employer to a worker complies with subsections (9) to (19).

(9) Power units on a suspended scaffold shall be equipped with

(a) positive pressure controls; and

(b) positive drives,

for raising and lowering the work platform.

(10) A manually operated suspended scaffold shall be equipped with a hoisting mechanism that has a secondary locking device that is securely locked in a positive drive position.

(11) Where two work platforms are tiered on one suspended scaffold, the upper platform shall have at least two independent means of support arranged so that the failure of one support will not result in the collapse of the upper platform.

(12) Subject to clause (19)(a), all supporting members of a suspended scaffold, including outriggers, parapet clamps, anchor points, parapet and work platforms shall be able to withstand four times the maximum load likely to be imposed on them.

(13) Counterweights on a suspended scaffold shall

(a) be securely attached to the outriggers;

(b) consist of solid material; and

(c) be of sufficient weight to counterbalance four times the rated capacity of the scaffold.

(14) Where the outrigger of a suspended scaffold does not have an eye bolt, the outer end of the outrigger shall be equipped with a positive stop device that prevents the movement of the rope.

(15) The maximum load that may be imposed on the components of an outrigger on a suspended scaffold shall be

(a) printed on each component; or

(b) otherwise accessible to the worker at the work area where the outrigger is located.

(16) An outrigger used in a suspended scaffold shall not be made of wood or include components made of wood.

(17) Any outrigger or parapet clamp used on a suspended scaffold shall be tied to an anchor point to prevent movement of the outrigger or parapet clamp.

(18) Where an outrigger on a suspended scaffold consists of more than one component, the components shall be fastened by at least two independent fastening systems to prevent the components from separating.

(19) A rope used to suspend a work platform shall

(a) be able to withstand ten times the maximum load likely to be imposed on the rope;

(b) where made of wire, be not less than 7.8 mm in diameter;

(c) where made of polypropylene, be not less than 16 mm in diameter; and

(d) in the case of a suspended scaffold that can be moved upward and downward,

(i) extend to the nearest safe surface, and

(ii) be secure from tangling or fouling.

(20) An employer shall ensure that a fall arrest system, including a ropegrab and an independent life line, is used by workers

(a) working on or from a suspended scaffold; and

(b) entering onto or leaving a suspended scaffold.

(21) Notwithstanding subsection (20), where a suspended scaffold has more than one means of support on each side of the work platform, either of which would prevent collapse of the scaffold in the event of the failure of the other, an employer may attach a fall arrest system to an adequate anchor point on the platform.

(22) Where a worker is performing work on a suspended scaffold, an employer shall ensure the work area below the work platform

(a) is roped off, barricaded or provided with a means of overhead protection; and

(b) has highly visible warning signs posted to notify workers of the overhead hazard.

(23) An employer shall ensure that

(a) all suspension lines, tiebacks, lifelines and other supporting components of a suspended scaffold that are made of rope; and

(b) the internal hoist mechanisms, are protected from abrasions, corrosive substances, other foreign materials, heat or work activities that might damage the rope or the internal hoist mechanisms.

Section 15 Bracket scaffold

15. An employer who provides a bracket scaffold for the use of a worker shall ensure that a bracket scaffold

(a) does not have brackets more than 3 m apart;

(b) is securely attached to the structural wall to prevent dislodging; and

(c) is erected, used, maintained and dismantled in accordance with

(i) the manufacturer's specifications, or

(ii) a professional engineer's design that includes instructions on erection, use, maintenance and dismantlement.

Section 16 Roofing bracket

16. An employer who provides a roofing bracket for the use of a worker shall ensure that a roofing bracket

(a) is erected and maintained to support four times the maximum load that is likely to be imposed on the bracket;

(b) is securely nailed to the roof;

(c) has a span of no more than 3 m; and

(d) is erected, used, maintained and dismantled in accordance with

(i) the manufacturer's specifications, or

(ii) a professional engineer's design that includes instructions on erection, use, maintenance and dismantlement.

Section 17 Use of industrial lift truck

17. (1) An employer shall ensure that an industrial lift truck is not used to lift a fork-lift platform where

(a) the ground or other conditions at a workplace may affect the stability of the industrial lift truck; or

(b) the industrial lift truck is susceptible to tipping, displacement or other destabilization.

(2) An employer shall ensure that a fork-lift platform is

(a) erected, used, maintained and dismantled in accordance with

(i) the manufacturer's specifications, or

(ii) a professional engineer's design that includes instructions on erection, use, maintenance and dismantlement;

(b) equipped with guardrails;

(c) securely attached to an industrial lift truck during use;

(d) operated at all times by a competent person, who shall be continuously at the controls where the platform is in an elevated position; and

(e) used only where a firm, flat surface ensures the stability of the industrial lift truck, unless otherwise specified by the manufacturer.

(3) While a worker is working on a fork-lift platform, the employer of the worker shall ensure that the worker is wearing a fall arrest system and that the fall arrest system is attached to an anchor point on the platform.

(4) An employer shall ensure that an industrial lift truck complies with CSA Standard B335-15 , "Safety standard for lift trucks".

(5) Where

(a) a fork-lift platform is in an elevated position; and

(b) a worker is on the platform,

the employer of the worker shall ensure the industrial lift truck supporting the work platform is not moved horizontally.

[EC2017-605, s. 1]

Section 18 Cantilevered scaffold - outrigger requirement

18. (1) An employer who provides a cantilevered scaffold for the use of a worker shall ensure that the cantilevered scaffold is erected, used, maintained and dismantled in accordance with

(a) the manufacturer's specifications, or

(b) a professional engineer's design that includes instructions on erection, use, maintenance and dismantlement.

(2) An employer shall ensure that a cantilevered scaffold is not used as a landing platform for loads deposited by a crane or hoist, unless

(a) fall protection is used by a worker using the scaffold; and

(b) a guardrail is placed at the entrance to the work platform when the work platform is not in use.

(3) An employer who provides a cantilevered scaffold for the use of a worker shall ensure that the cantilevered scaffold is equipped with a fully decked work platform.

Section 19 Power operated elevating work platform

19. (1) An employer who provides a power operated elevating work platform for the use of a worker shall ensure that the work platform is equipped with

(a) positive pressure controls for the positioning of the work platform;

(b) a power elevating mechanism equipped with positive drives for both raising and lowering the work platform;

(c) an interlock device that limits lateral movement when the height of the work platform exceeds that specified by the manufacturer; and

(d) an elevating mechanism that, upon failure, locks the work platform in the elevated position.

(2) Where an elevating mechanism referred to in clause (1)(b) of a power operated elevating work platform fails while a worker is working on the work platform, the employer who provided the work platform for the use of the worker shall ensure that the worker is removed from the work platform before

(a) the work platform is lowered; or

(b) repairs are made to the elevating mechanism.

(3) Where the operator of a power operated elevating work platform is not the worker being raised on the work platform, the employer who provided the work platform for the use of the worker shall ensure that there is an effective and direct means of communication between the operator and the worker.

(4) The owner of a power operated elevating work platform, and an employer who provides a power operated elevating work platform for the use of a worker, shall ensure that the power operated elevating work platform is designed, constructed, erected, maintained, inspected, monitored and used in accordance with the following CSA Standards, as applicable:

(a) B354.1-04 , "Portable Elevating Work Platforms";

(b) B354.2-01 , "Self Propelled Elevating Work Platforms";

(c) B354.4-02 , "Self-propelled Boom-supported Elevating Work Platforms";

(d) Z271-10 , "Safety Code for Suspended Elevating Platforms";

(e) C225-10 , "Vehicle-Mounted Aerial Device".

(5) An employer who provides a power operated elevating work platform for the use of a worker shall ensure that

(a) the worker is competent to operate the platform or that the platform is operated by another worker who is competent to do so; and

(b) the worker operating the platform has available on the work platform

(i) a legible operator's manual, and

(ii) information on

(A) all of the applicable operational limitations and requirements, including those relating to the use of outriggers, stabilizers and extendable axles,

(B) the specific surface conditions required for safe use in the elevated position,

(C) such warnings as may be specified by the manufacturer;

(D) the name and number of the CSA Standard to which the power operated elevating work platform was designed, and

(E) the name and address of the owner of the work platform.

(6) An employer who provides a power operated elevating work platform for the use of a worker shall ensure that information on

(a) the rated capacity of the work platform; and

(b) other than for a boom-type elevating work platform, the direction of the machine movement for each operating control of the work platform, is securely posted at the controls of the work platform.

(7) The owner of a power operated elevating work platform shall keep a permanent record of all inspections, tests, repairs, modifications and maintenance performed on it.

(8) The record required under subsection (7) shall include the name and signature of the person who performed the inspection, test, repair, modification or maintenance.

(9) An employer who provides a power operated elevating work platform for the use of a worker shall ensure that the worker who operates the work platform has, before using it for the first time,

(a) received oral or written instruction on the safe operation of the particular work platform; or

(b) otherwise been adequately trained to operate the work platform.

(10) An employer shall ensure that the instruction and training required by a worker under subsection (9) is provided by a competent person and includes

(a) instruction

(i) on the manufacturer's specifications,

(ii) on applicable load limitations,

(iii) on the kind of surfaces on which the power operated elevating work platform are designed to be used; and

(b) a hands on demonstration of the proper use of all controls.

(11) An employer who provides a power operated elevating work platform for the use of a worker shall ensure that the work platform

(a) is not loaded in excess of its rated capacity;

(b) is used on a firm, level surface unless otherwise specified by the manufacturer;

(c) is used only in accordance with the manufacturer's specifications;

(d) is not loaded and used in such a manner as to create an unstable condition or cause a hazard;

(e) is not moved vertically or horizontally unless every worker on the scaffold, while it is being moved, is protected against falling by a fall arrest system that complies with the Fall Protection Regulations (EC633/04); and

(f) is equipped with an emergency stop button.

(12) An employer of a worker who uses a power operated elevating work platform shall ensure that the worker is protected against falling by a fall arrest system that complies with the Fall Protection Regulations (EC633/04).

[EC2017-605, s. 2]

Section 20 Crane or hoist suspended work platforms

20. (1) An employer shall not provide a crane supported work platform for the use of a worker unless the work to be performed by the worker cannot be done from a scaffold in a safe and practical manner.

(2) An employer who provides a crane supported work platform for the use of a worker shall ensure, where a hoist is used to suspend the work platform, that the design of the hoist is certified by a professional engineer before the work platform is suspended from the hoist.

(3) An employer who provides a crane supported work platform for the use of a worker shall ensure that the crane or hoist used to suspend the work platform

(a) is operational in the power up and power down positions;

(b) is equipped with an automatic brake system that operates when the crane or hoist is not lifting or lowering;

(c) is equipped with an anti-two block device;

(d) is operated at a safe lifting and lowering speed; and

(e) has at least three full wraps on the hoisting drum at all times.

(4) An employer who provides a crane supported work platform for the use of a worker shall ensure that the operator of the crane or hoist used to suspend the work platform has a constant means of communication with the worker on the work platform.

(5) An employer who provides a crane supported work platform for the use of a worker shall ensure that the work platform has a secondary means of support that is

(a) shackled above the ball of the crane; and

(b) able to support the platform if the primary means of support fails.

(6) An employer who provides a commercially manufactured crane supported work platform for the use of a worker shall ensure that the work platform is erected, used, maintained and dismantled in accordance with the manufacturer's specifications.

(7) An employer shall, before providing a crane supported work platform that is not commercially manufactured for the use of a worker, ensure that

(a) the design of the work platform is certified by a professional engineer; and

(b) the work platform is erected, used, maintained and dismantled in accordance with the certified design.

(8) An employer who provides a crane supported work platform for the use of a worker shall ensure that a fall arrest system, attached to an anchor point on the work platform, is used by workers working from or otherwise present on the work platform.

Section 21 Lifting in certain equipment prohibited

21. Except as expressly permitted in these regulations or in another enactment, an employer shall ensure that workers are not lifted or held aloft in equipment, such as loader buckets or backhoes, that is not specifically designed for that purpose.