Excavation and Trenches

[OHS General Regs., S. x] Follow these links

to related legislation.

Highlighted words reveal

definitions and supplementary

information when selected.

Working around or in excavations and trenches can be dangerous work. Worksites with excavations and trenches can be busy places with a lot going on, so it is important that workers stay alert to any potential hazards and follow all workplace procedures. Hazards can include poor air quality, injury by heavy machines, falling debris, or electric shock.

Employer Duties

Employers must:

- Before digging, determine the location of all underground utility lines and pipes and notify the authorities in charge of those utilities. Before performing any work in these areas, make sure utility lines are de-energized and grounded.

- When an excavation or trench is within 609 mm (2 ft.) of any underground utility line or piping, develop relevant operating procedures for working near underground utilities and ensure workers follow those procedures.

- Make sure an excavation that is more than 1 219 mm (4 ft.) deep is 3048 mm (10 ft.) away from any utility poles, posts or similar structures. If this is not possible, support or remove these structures. [OHS General Regs., S. 12.1]

- Make sure all supports or bracing are able to withstand any load within the excavation or trench until that project is completed. [OHS General Regs., S. 18.1]

- Ensure workers do not enter an excavation or trench 1 219mm (4 ft.) or more in depth, unless wearing CSA approved headwear and footwear. [OHS General Regs., S.12.3] [OHS General Regs., S. 45.5] [OHS General Regs., S. 45.15]

- Never allow workers to install or remove shoring from a position inside a trench as they could be injured by falling debris as the supports are removed.

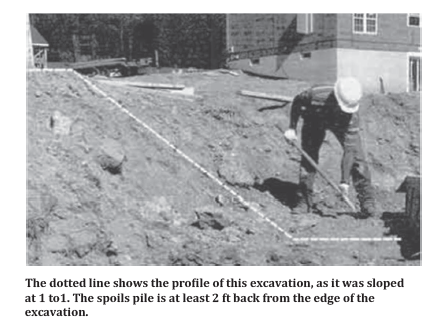

- Keep excavated material at least 609 mm (2 ft.) away from the edge of the excavation or trench. [OHS General Regs., S. 12.5]

- Keep the excavation and trench reasonably free of water. Use a pump or drainage system if needed. [OHS General Regs., S. 12.6]

- Never store hazardous liquids or gases and explosives in excavations or trenches and make sure any hazardous liquids or gases (include exhaust from engines are used in or near excavations or trenches) do not build up in the excavation or trench. Ventilate the excavation or trench if necessary. [OHS General Regs., S. 12.6]

- Provide a signaller if the operator has restricted visibility when lowering material into an excavation or trench. [OHS General Regs., S. 12.7]

- Station a worker on the surface to observe when others are working in an excavation or trench.

- Never allow workers to stand under loads or in areas where loads could land. It is also good practice to make sure workers keep aware of loads and how to avoid unsafe contact with them. Stay away from vehicles, like dump trucks, that may be loading or unloading material. Drivers should remain in the cabs of their vehicles.

- Support walls and crests cut into solid rock, if they are not stable, with rock bolts, wire mesh or shoring or another equivalent method. [OHS General Regs., S. 12.10]

- Make sure the excavation or trench is adequately illuminated, has warning lights, and has a barricade at all times when workers are working in the excavation or trench.

- Make sure excavation or trench is protected by erecting barricades and use adequate warning lights at night.[OHS General Regs., S.12.11(2)]

- Use warning lights to make sure people, can see materials along side an excavation or trench that may be in the way of traffic. [OHS General Regs., S. 12.12]

- Make sure the excavation or trench is properly lighted when work is done at night. [OHS General Regs., S.12.13]

- Make sure digging does not occur if it will affect the stability of a neighbouring building or structure. [OHS General Regs., S.12.15]

- Provide workers with a safe way to enter and exit the excavation or trench, such as ladders or ramps.

- After a demolition, fence off or backfill a basement or excavation to grade level. [OHS General Regs., S. 27.17]

- After a blasting operation and before continuing any work in an excavation, scale loose rocks off its sides to eliminate the hazard of falling rocks. [OHS General Regs., S. 26.59]

Traffic Control Near an Excavation or Trench

If the construction in or around an excavation or trenching interferes with the flow of traffic, the employer must: [OHS General Regs., S. 12.12]

- Post warning signs for both directions of traffic flow. Warning signs must be at least 225 m (738 ft.) from the worksite, and at all intersections between the signs.

- Provide trained signallers to direct the flow of traffic, when it could endanger workers nearby.

- Provide signallers with reflectorized vests or jackets and paddles for use while directing traffic.

Power Shovels

Power shovels, such as excavators and bulldozers, must be used with care and from safe locations. [OHS General Regs., S. 12.14] Keep workers away from power shovels that may be a crushing hazard.

Distribute a power shovel's load on soft ground by using mats or heavy planking. [OHS General Regs., S. 12.14]

If a power shovel is on the bank of the excavation or trench, prevent any potential cave-ins by installing shoring or bracing. [OHS General Regs., S. 12.14]

Excavations 1219 mm (4 ft.) or deeper

When workers must enter excavations that are 1 219 mm (4 ft.) or deeper, the employer must:

- Scale down the sides and crests to prevent loose material from falling into the excavation or trench.

- Install ladders, extending at least 914 mm (3 ft.) above the excavation or trench. Ladders must be located no more than 15 240 mm (50 ft.) from where workers are working. Alternatively provide another equally safe means to enter and exit.

- Provide workers with CSA approved headwear and footwear. Make sure the workers use the provided equipment.

Shoring, bracing or caging is required to maintain the strength and stability of an excavation or trench walls (when it is not cut in solid rock) when it is over 1 219 mm (4 ft.) deep. Shoring and bracing must be certified as adequate by a professional engineer. Proof of certification must be available for inspection. [OHS General Regs., S. 12.2]

Alternatively, slope back the sides so that the earth's slope starts above the 1 219 mm (4 ft.) depth and is maintained thereafter at a 45-degree angle. In other words, for every 305 mm (1 ft.) of vertical trench, above 1 219 mm (4 ft.), the slope must be cleared back by at least 305 mm (1 ft.) horizontal.

No shoring, bracing or caging is required if people will not be entering the excavation or trench. Add additional shoring and bracing as necessary if there is going to be increased pressure on an excavation or trench's walls because of mobile equipment. [OHS General Regs., S. 12.2]

Excavations 1828 mm (6 ft.) or deeper

When excavations or trenches more than 1 828 mm (6 ft.) deep are cut into the rock, employers must: [OHS General Regs., S.12.5]

- Locate the excavated rock or other granular material away from the excavation or trench at a distance of at least equal to the height of the pile.

- Install a fence at least 914 mm (3 ft.) from the face of the excavation or trench. Make sure the fence is made of material strong enough to support the pile.

Bracing and supports

Make sure all bracing and supports can safely support all loads to which it may be subjected at all stages of progress on the project. [OHS General Regs., S. 18.1]

Formwork

All footings for shores must be rigid and able to carry the maximum expected load without settlement or deformation. When using concrete for shoring and other purposes in an excavation, make sure it is designed to withstand any likely loads throughout the project. This bracing may include sufficient diagonal bracing to prevent sideways movement of the formwork or buckling of the shores. [OHS General Regs., S. 19.1]

Pedestrians Near Excavations and Trenches on Constructions Sites

If a construction or demolition site is 2 130 mm (84 in.) or closer to a sidewalk or another path used by pedestrians, build a covered way over the pedestrian path or sidewalk before beginning any work. A covered way must: [OHS General Regs., S. 20.2] [OHS General Regs., S. 20.3]

- Be at least 2 440 mm (96 in.) tall.

- Be at least 1 500 mm (60 in.) wide.

- Be designed and constructed to support at least 245 kg per m2 (50 lbs. per sq. ft.) on its roof and safely any loads it is likely to be subjected to during its use.

- Have a weather-tight roof sloped toward the project.

- Have a railing 1 067 mm (42 in.) in height on its street side.

- Board up the side facing the construction site and have a smooth surface facing any pedestrian traffic.

- If the work only involves a structure of one story or less, fencing or boarding at least 1 800 mm (72 in.) may be all that is necessary. Seek the written opinion of an officer to determine if fencing or boarding is adequate.

If a construction or demolition site is 2 130 mm (84 in.) or more from a sidewalk or other paths used by pedestrians, fencing or boarding not less than 1 800 mm (72 in.) high may be needed to protect those walking by the construction site. [OHS General Regs., S. 20.3]

Worker Duties

Workers must:

- Wear all provided personal protective equipment (PPE) (CSA approved headwear and footwear), including reflectorized paddles and vests or jackets. [OHS General Regs., S. 12.3]

- Not enter an excavation or trench 1 219 mm (4ft.) or deeper without wearing headwear and footwear. [OHS General Regs., S.12.3(b)]

- Not install or remove shoring while workers are inside a trench. [OHS General Regs., S. 12.4]

- Not lower material into an excavation without a signaller if they have restricted visibility. [OHS General Regs., S. 12.7]

- Not stand under any loads or in an area where a load could land. [OHS General Regs., S. 12.9]

To access these, you must first create an account with "CSA Communities".

Go to: https://community.csagroup.org/login.jspa?referer=%252Findex.jspa

Once you are logged in, click on the text below the "OHS Standards / View Access" graphic.

Click on the jurisdiction of your choice to see the CSA Standards as referenced in that legislation.

Standards may also be purchased from CSA Group: https://store.csagroup.org/

General Regulations

EC180/87

Part 12 EXCAVATIONS, TRENCHES AND CONSTRUCTION

Section 12.1 Location of utility lines

12.1 (1) The employer shall ensure that before beginning an excavation or trench, the location of possible underground utility lines and piping is determined.

(2) The employer shall ensure that when working within 609 mm (2 ft.) of underground utility lines and piping

(a) adequate safety precautions are taken;

(b) utility lines have been de-energized and grounded; and

(c) the authority operating the utility has been notified of the operation.

(3) The employer shall ensure that an adequate operating procedure is used when workers are working within 609 mm (2 ft.) of any underground utility line or piping.

(4) The employer shall ensure that utility poles, posts or similar structures are supported or removed when they are within 3 048 mm (10 ft.) of an excavation or trench more than 1 219 mm (4 ft.) deep.

[EC2021-126, s. 3]

Section 12.2 Shoring

12.2 (1) The employer shall ensure that the walls of an excavation or trench are supported by adequate shoring and bracing or caging except when an excavation or trench

(a) is less than 1 219 mm (4 ft.) deep;

(b) is cut in solid rock;

(c) is sloped to within 1 219 mm (4 ft.) of the bottom of the excavation or trench with a slope at the angle of repose that does not exceed 305 mm (1 ft.) of vertical rise to each 305 mm (1 ft.) of horizontal run; or

(d) is such that workers are not required to enter.

(2) If necessary to provide protection to workers working in a trench the employer shall ensure that additional shoring and bracing is added to support the increased pressure due to the location of mobile equipment at the edge of an excavation or trench.

(3) The employer shall ensure that shoring and bracing for excavations or trenches is certified as adequate by a professional engineer and the proof of certification is made available to an officer on request.

[EC2021-126, s. 3]

Section 12.3 Safety requirements before entry

12.3 The employer shall ensure that workers are not allowed to enter an excavation or trench 1 219 mm (4 ft.) or more in depth, and workers shall not enter unless

(a) the requirements of section 12.2 are complied with;

(b) CSA approved safety headwear and footwear are provided and worn by the workers, as specified in sections 45.5 or 45.15, as the case may be;

(c) ladders, extending at least 914 mm (3 ft.) above the excavation or trench are installed and located no more than 15 240 mm (50 ft.) from where workers are working or other safe means of access and egress are provided;

(d) the sides and crests have been scaled down to prevent loose material from falling into the excavation or trench.

[EC2021-126, ss. 3, 20]

Section 12.4 Removal, etc. of shoring

12.4 (1) The employer shall ensure than a worker does not install or remove shoring from a position inside a trench.

(2) A worker shall not install or remove shoring from a position inside a trench.

[EC2021-126, s. 3]

Section 12.5 Excavated material

12.5 (1) The employer shall ensure that excavated material is kept at least 609 mm (2 ft.) away from the edge of excavations or trenches.

(2) The employer shall ensure that where piled rock or other granular material creates a hazard above an excavation or trench more than 1 828 mm (6 ft.) deep in rock

(a) the pile is located back from the face of the excavation or trench a distance equal to at least the height of the pile; or

(b) a fence is erected at a minimum distance of 914 mm (3 ft.) from the face of the excavation or trench, consisting of material adequate to support the pile.

Section 12.6 Water

12.6 (1) The employer shall ensure that every excavation and trench is kept reasonably free of water.

(2) The employer shall ensure that hazardous liquids or gases and explosives are not stored in excavations or trenches.

(3) When hazardous liquids or gases or internal combustion engines are used in or near excavations or trenches, or where hazardous liquid or gases may enter or be present in an excavation or trench, the employer shall ensure that adequate ventilation precautions are taken to prevent the accumulation of hazardous gases in the excavation or trench.

Section 12.7 Lowering materials

12.7 The employer shall ensure that no operator lowers material into an excavation or trench and no operator shall lower material into an excavation or trench unless

(a) the operator has unrestricted visibility; or

(b) a signaller is used to direct the movement of the material.

Section 12.9 Standing under loads

12.9 Workers in an excavation or trench shall not stand under any load or in the area where a load may land.

[EC2021-126, s. 3]

Section 12.10 Wall supports

12.10 The employer shall ensure that the walls and crests of an excavation or trench, when cut in solid rock and are not stable, are supported by rock bolts, wire mesh or shoring or other equivalent method.

Section 12.11 Warning lights and barricades

12.11 (1) The employer shall ensure that an excavation or trench is adequately illuminated, has adequate warning lights conspicuously displayed, and has a barricade at all times while workers are working in the excavation or trench.

(2) Where an excavation or trench is made, the employer shall ensure that

(a) adequate barricades are erected; and

(b) at night, adequate warning lights are used.

[EC2021-126, s. 3]

Section 12.12 Illumination of materials

12.12 (1) When materials piled along the sides of any excavation or trench interfere with the flow of traffic, the employer shall ensure that the material is adequately illuminated by warning lights.

(2) When construction work is being carried out which interferes with the flow of traffic, the employer shall ensure that adequate warning signs are posted in both directions not less than 225 m (738 ft.) from the worksite, and at any intersection between the warning signs.

(3) When construction work is being carried out in areas where worker safety is endangered by vehicle traffic, the employer shall provide trained signallers to control the flow of traffic.

(4) The employer shall provide and all signallers shall wear a reflectorized vest or jacket when controlling the flow of traffic.

(5) The employer shall provide and all signallers shall use reflectorized paddles to control the flow of traffic.

[EC2021-126, s. 3]

Section 12.13 Night lighting

12.13 Where work is done at night, the excavation or trench shall be properly lighted.

Section 12.14 Power shovels

12.14 (1) Power shovels shall be located with care.

(2) Where a power shovel is placed on the bank of an excavation or trench, shoring and bracing shall be used to prevent a cave-in.

(3) Mats or heavy planking shall be used to distribute the load on soft ground.

Section 12.15 Adjacent buildings

12.15 No person shall dig an excavation that is likely to endanger a worker by affecting the stability of an adjacent building or structure.

Part 18 BRACING AND SUPPORTS DURING CONSTRUCTION

Section 18.1 Bracing and supports

18.1 The employer shall ensure that sufficient bracing and supports, either permanent or temporary, shall be provided to ensure that a structure, or any part thereof, will safely support all loads to which it may be subjected at all stages of progress on the project.

Part 19 FORMWORK

Section 19.1 Formwork

19.1 (1) Every employer shall ensure that

(a) every structure and every part of a structure for the purpose of forming concrete shall be designed, constructed, supported and braced to safely withstand all loads likely to be applied to it before, during and after the placing of concrete;

(b) where shores are used, the bracing required by clause (a) shall include sufficient diagonal bracing in the vertical and horizontal planes to prevent lateral movement of the formwork and buckling of the shores;

(c) where shoring is more than one tier in height, the junction of each tier shall be braced to prevent any lateral movement.

(2) The employer shall ensure that footings for shores shall be sound, rigid and capable of carrying the maximum load without excessive settlement or deformation.

Part 20 FENCING AND BARRICADES

Section 20.2 Covered way

20.2 A covered way shall

(a) have a clear height of not less than 2 440 mm (96 in.);

(b) have a clear width of not less than 1 500 mm (60 in.);

(c) be designed and constructed to support safely all loads that may be reasonably expected to be applied to it, but in no case less than 245 kg per m2 (50 lbs. per sq. ft.) on the roof;

(d) have a weather-tight roof sloped toward the project;

(e) be totally enclosed on the project side so that there is a reasonably smooth surface on the sidewalk side of that enclosure; and

(f) have a railing 1 067 mm (42 in.) in height on the street side.

Section 20.3 Fences

20.3 Where a building or other structure being constructed, altered, repaired or demolished is located 2 130 mm (84 in.) or more from a sidewalk or other public way used by pedestrians, a substantially constructed fence or boarding not less than 1 800 mm (72 in.) high shall be constructed if, in the written opinion of an officer, the persons using the sidewalk or other public way might be endangered.

Part 26 EXPLOSIVES

Section 26.59 Loose rocks

26.59 Loose rocks shall be scaled off sides of excavations after blasting operations in order to eliminate the hazard of falling rocks before work is resumed.

Part 27 DEMOLITION

Section 27.17 Basement or excavation

27.17 Following demolition of a structure, any basement or similar excavation shall

(a) be fenced or barricaded; or

(b) if construction is not to proceed forthwith, be backfilled to grade level.

Part 45 PERSONAL PROTECTIVE EQUIPMENT

Section 45.5 Standard head protection

45.5 The employer shall ensure that a worker on a worksite or at any other place of employment who is exposed to a hazard, which could injure the head, wears head protection appropriate to the hazard and which meets the requirements of CSA Standard Z94.1 , Industrial Protective Headwear - Performance, Selection, Care and Use.

[EC2021-126, ss. 3, 41]

Section 45.15 Footwear

45.15 The employer shall ensure that a worker on a worksite or at any place of employment who is exposed to a hazard which could injure the foot wears footwear which meets the standards and specifications of CSA Standard Z195-14 Protective Footwear or a standard offering equivalent protection.

[EC2021-126, ss. 3, 43]