Ladders

[OHS General Regs., S. x] Follow these links

to related legislation.

Highlighted words reveal

definitions and supplementary

information when selected.

Falls from ladders are common across many industries, including the construction industry. While used widely in many workplaces, it is important to treat ladders with the same care and caution as any piece of equipment. Make sure the ladder being used is suited to the task. Using the incorrect type of ladder or one that is too short or tall can result in falls and injuries. As well, workers must make sure to use ladder safely and according to established best practices, such as maintaining 3 points of contact, and avoid overreaching or twisting while on a ladder.

Employers Duties

Employers must:

- Inspect the ladders before each use.

- Keep their bodies centered between the side rails, when standing on a ladder.

- Ascend and descend them facing the ladder and using both hands.

- Do not use benches, boxes, tables or other makeshift substitutes as ladders.

- Do not work from the top three rungs of a single or extension ladder.

- Do not lash or splice ladders together.

- Do not place a ladder in front of or against a door unless that door is locked, propped open, or guarded.

Setting up the ladder

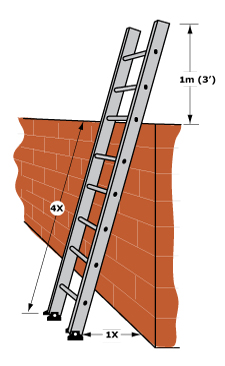

When using a ladder, the user must make sure: [OHS General Regs., S. 23.2]

- the base of an inclined portable ladder is not more than a ¼ of the length out from the vertical line (at the top of the ladder), unless the top is securely fastened;

- the side rails have secure footing;

- the top rest is rigid and has enough strength to support the load applied;

- where possible, the top of the ladder is securely fastened to prevent it from moving;

- the side rails of a portable ladder must be at least 914 mm (3 ft.) above a landing; and

- the side rails are not less than 305 mm (12 in.) apart for ladders that are 3048 mm (10 ft.) in length, and this distance increases 6 mm (1.4 in.) in width for each additional 300 mm (1 ft.) in length.

Specific requirements

Metal ladders

Do not allow metal ladders and ladders made with reinforcing wire or other conducting material to be used near energized electrical conductors or equipment. [OHS General Regs., S. 36.24]

Step ladders [OHS General Regs., S. 23.5]

- Do not use step ladders over 6 096 mm (20 ft.) in length.

- Do not use the top step of a step ladder and make sure it and the material shelf are clearly marked to show they are not safe to step on.

- All metal parts of step ladders must be made of malleable iron, wrought iron or steel.

A step ladder must have: [OHS General Regs., S. 23.5]

- A front section with a minimum slope of 89 mm (3 ½ in.) and a back section with a minimum slope of 50 mm (2 in.) in each 305 mm (12 in.) length of side rail when in the open position.

- A minimum inside width of 305 mm (12 in.) between side rails at the top step.

- Level treads.

- Side rails with an additional spread of 25 mm (1 in.) for each 305 mm (12 in.) of the step ladder’s length.

- Metal braces to lock the legs securely in position.

- Back legs that are equally thick as its side rails and at least 44 mm (1 3/4 in.) wide.

- Cross rails and braces that are securely fastened and at least 13 mm (½ in.) thick.

- Bottom cross rail and diagonal braces that are 3 048 mm (10 ft.) and less in height.

- Bottom and intermediate cross rails and two sets of diagonal braces that are over 3 048 mm (10 ft.) in height.

- Cross rails that are at least 100 mm (4 in.) wide and diagonal braces that are at least 50 mm (2 in.) wide.

- Reinforced at each step by a metal tie rod or brace.

- Side rails with the solid cross section or equivalent strength cross listed in the table below.

| Length of side rail (ft.) | Minimum thickness | Minimum width |

|---|---|---|

| Up to and including 10 | 19 mm (3/4 in.) | 70 mm (2 3/4 in.) |

| Over 10 and up to and including 12 | 19 mm (3/4 in.) | 76 mm (3 in.) |

| Over 12 and up to and including 16 | 19 mm (3/4 in.) | 82 mm (3 1/4 in.) |

| Over 16 and up to and including 20 | 25 mm (1 in.) | 82 mm (3 1/4 in.) |

Wooden ladders

Wooden ladders must: [OHS General Regs., S. 23.4]

- be made of good quality, straight grained lumber;

- not be painted with anything other than a clear protective coating;

- have side rails 50 mm x 100 mm (2 in. x 4 in.) lumber if they are made on a construction site;

- have rungs that are free of knots;

- be designed to safely carry a load 200 kg (450 lbs.) on the centre of the rung;

- have uniformly spaced rungs that are not more than 300 mm (12 in.) apart;

- have side rails that are dressed on all sides with any sharp edges taken off and free from splinters; and

- be the minimum size set out in the table below.

| Length of Ladder (ft.) | Thickness | Depth |

|---|---|---|

| Up to and including 20 | 29 mm (1 1/8 in.) | 64 mm (2 ½ in.) |

| Over 20 and up to and including 22 | 31 mm (1 1/4 in.) | 70 mm (2 3/4 in.) |

| Over 22 and up to and including 30 | 31 mm (1 1/4 in.) | 76 mm (3 in.) |

Flat rungs on a wooden ladder must be at least 25 mm (1 in.) by 64 mm (2 ½ in.) and secured to each side with at least three screws or wire nails. They must also be notched into the side rails at least 13 mm (½ in.) on the lower side, or with fillers installed between the rungs. [OHS General Regs., S. 23.4]

Round rungs on a wooden ladder must be at least 31 mm (1 1/4 in.) in diameter with tenons 6 mm (1/4 in.) less in diameter fitting through the side rails and secured with a screw or wire nail through tenon at mid-length. [OHS General Regs., S. 23.4]

Additional requirements

- Powered mobile equipment must have a ladder or steps (usually permanently mounted on the side of the equipment) to safely access the controls. [OHS General Regs., S. 33.18]

- On construction sites, employers must provide a safe way to access the working areas that are above or below ground by with stairs, runways, ramps, scaffolds or ladders in good condition. [OHS General Regs., S. 15.2]

- Do not allow workers to enter an excavation or trench without a safe entrance and exit. If using a ladder, they must extend at least 914 mm (3 ft.) above the excavation or trench and be no more than 15 240 mm (50 ft.) from where workers are working. [OHS General Regs., S. 12.3]

- If the pitch of a stairway would be greater than 50 degrees use a fixed ladder instead of stairs. [OHS General Regs., S. 22.6]

- Tanks that are over 1 200 mm (4 ft.) deep and contain liquids need to have ladders that are fixed to the outside only, in addition to a fixed permanent cover and manholes close to the bottom. [OHS General Regs., S. 40.5]

- Tanks used for storing non-flammable hazardous liquids must be above ground or floor level and have stairways or permanent ladders for convenient and safe access to all parts of the tanks. [OHS General Regs., S. 43.9]

- Bins for storing dry bulk materials must have stairways or permanent ladders outside for convenient and safe access to all parts of the bin. [OHS General Regs., S. 43.35]

Worker responsibilities

- Never use benches, boxes, tables or other makeshift substitutes as ladders. [OHS General Regs., S. 23.1]

- Do not work from the top three rungs of a single or extension ladder. [OHS General Regs., S. 23.3]

- Do not lash or splice ladders together. [OHS General Regs., S. 23.3]

- Do not place a ladder in front of or against a door unless that door is locked, propped open or guarded. [OHS General Regs., S. 23.3]

- Inspect ladders before each use. [OHS General Regs., S. 23.3]

- Ascend and descend facing the ladder and using both hands. [OHS General Regs., S. 23.3]

- Keep the centre of your body between the side rails, when standing on a ladder. [OHS General Regs., S. 23.3]

- Inspect ladders before using them and do not use a ladder that is broken or defective in some way. [OHS General Regs., S. 29.5]

- Report a broken or unsafe ladder to your employer. [OHS General Regs., S. 29.5]

- Maintain ladders in safe working condition and only use as intended. [OHS General Regs., S. 29.5]

- Store ladders when they are not being used so that they are maintained in good condition. [OHS General Regs., S. 29.5)]

- Do not store or leave ladders in hallway, stairways or other places where work is being performed or people may pass by. [OHS General Regs., S. 29.5]

- Do not store or leave ladders in where it could fall on people below. [OHS General Regs., S. 29.5]

- Inspect ladders before each use. [OHS General Regs., S. 23.3]

- Report any unsafe or damaged ladders to the employer. [OHS General Regs., S. 23.3]

- Do not work from the top three rungs of a single or extension ladder. [OHS General Regs., S. 23.3]

General Regulations

EC180/87

Part 12 EXCAVATIONS, TRENCHES AND CONSTRUCTION

Section 12.3 Safety requirements before entry

12.3 The employer shall ensure that workers are not allowed to enter an excavation or trench 1 219 mm (4 ft.) or more in depth, and workers shall not enter unless

(a) the requirements of section 12.2 are complied with;

(b) CSA approved safety headwear and footwear are provided and worn by the workers, as specified in sections 45.5 or 45.15, as the case may be;

(c) ladders, extending at least 914 mm (3 ft.) above the excavation or trench are installed and located no more than 15 240 mm (50 ft.) from where workers are working or other safe means of access and egress are provided;

(d) the sides and crests have been scaled down to prevent loose material from falling into the excavation or trench.

[EC2021-126, ss. 3, 20]

Part 15 ACCESS TO WORKPLACES

Section 15.2 Access to construction site

15.2 On construction sites the employer shall ensure that means of access to every excavation, floor, platform and fixed scaffold where work is being performed above or below ground level shall

(a) be provided by a stair, runway, ramp, scaffold or ladder; and

(b) be maintained in place and in safe condition at all times.

Part 22 STAIRS

Section 22.6 Obligations of employer regarding stairs

22.6 The employer shall ensure that

(a) stairs and platforms made of perforated material shall not contain openings larger than 11 mm;

(b) stairs, except service stairs which may be used for access to oiling platforms, machinery, etc., should be not less than 900 mm;

(c) the pitch of stairways except service stairways should be between 30 degrees and 35 degrees from horizontal and shall in no case be less than 20 degrees or more than 50 degrees;

(d) where the pitch would be less than 20 degrees a ramp shall be used and where the pitch is greater than 50 degrees a fixed ladder shall be used;

(e) head room with a vertical clearance of 2050 mm from the top of the tread on a line with the face of the riser, shall be provided at all points in the stairwell;

(f) except for service stairs, the treads exclusive of nosings or projections shall be not less than 280 mm in depth and the risers shall not be more than 180 mm or less than 125 mm in height;

(g) the width of the treads and the height of the risers shall be constant in any flight and all stairways having three or more risers shall be equipped with stair railings on any open side;

(h) the top and the bottom treads of any flight shall be clearly distinguishable;

(i) enclosed stairways less than 1100 mm wide shall be equipped with at least one handrail, preferably on the right side descending and two handrails on curved stairways;

(j) stairways 1100 mm or more in width shall be equipped with one stair railing on each open side and one handrail on each enclosed side;

(k) Repealed. [EC2024-600, s. 16]

(l) Repealed. [EC2024-600, s. 16]

(m) the height of stair railings from the upper surface of the top rail to the surface of the tread in line with the face of the riser at the forward edge of the tread, shall not be less than 865 mm and not more than 1070 mm;

(n) wooden handrails shall be at least 50 mm x 50 mm in size and of smooth finish;

(o) metal handrails shall be at least 38 mm in diameter;

(p) handrails mounted directly on walls or partitions shall be fixed by means of brackets attached to the lower side of the rails so as not to interfere with the continuity of the rails;;

(q) brackets shall be spaced not more than 1.2 m apart, measured on the horizontal plane, and shall provide a clearance of at least 50 mm between the rails and the walls or any obstruction on the walls;

(r) handrail structure shall be capable of withstanding a load of 0.9 kN applied in any direction at any point of the rail;

(s) the clear width of service stairs shall be at least 914 mm;

(t) the pitch of service stairs shall not be more than 50 degrees and the width of the treads shall not be less than 152 mm;

(u) stairways shall be adequately illuminated and lights shall be located so that they do not cause glare;

(v) a non-slip nosing or strip shall be used on all stair treads on which there is danger of slipping due to the material of the tread;

(w) a non-slip nosing or strip shall be installed within a distance of 31 mm from the front edge of the tread and shall be at least 30 mm wide;

(x) treads and landings of exterior exit stairs more than 10 m high shall be designed to be free of ice and snow accumulation.

[EC2024-600, s. 16]

Part 23 LADDERS

Section 23.1 Use of ladders

23.1 (1) The employer shall provide a ladder where workers must work in an elevated or sub-level area not provided with other safe and recognizable means of access or egress.

(2) The employer shall ensure that a ladder is removed from service when it has loose, broken or missing rungs, split side rails or other hazardous defects.

(3) The employer shall ensure that

(a) all portable ladders shall be equipped with non-slip bases;

(b) portable metal or wire truss ladders shall not be used in the vicinity of electrical circuits or apparatus when the hazard of electrical exposure is present;

(c) benches, boxes, tables or other makeshift substitutes shall not be used as ladders.

[EC2021-126, s. 3]

Section 23.2 Specifications

23.2 The user of a ladder shall ensure that

(a) the base of an inclined portable ladder shall not be more than one-fourth the length of the ladder out from the vertical line of contact at the top unless the top is securely fastened;

(b) side rails of ladders when in use shall have secure footing and the top rest shall be rigid and have ample strength to support the applied load;

(c) where possible the top of the ladder shall be securely fastened to prevent movement;

(d) the side rails of a portable ladder shall extend at least 914 mm (3 ft.) above a landing;

(e) side rails have a uniform clear width between them not less than 305 mm (12 in.) for ladders 3 048 mm (10 ft.) in length and under, and increasing 6 mm (1/4 in.) in width for each additional 300 mm (1 ft.) in length.

Section 23.3 General obligations

23.3 The user of a ladder shall

(a) inspect a ladder before use;

(b) report any unsafe condition of the ladder to the employer;

(c) not work from the top three rungs of a single or extension ladder;

(d) not lash or splice ladders together;

(e) not place a ladder in front of or against a door unless the door is blocked in the open position, locked or guarded;

(f) use both hands and face the ladder when ascending or descending;

(g) when standing on a ladder, keep the centre of his body between the side rails.

Section 23.4 Wooden ladders

23.4 The employer shall ensure that a wooden ladder

(a) is made of good quality, straight grained lumber;

(b) is not painted other than by being preserved with transparent protective coating;

(c) if made on a construction site shall have side rails 50 mm x 100 mm (2 in. x 4 in.) lumber;

(d) has rungs

(i) free of knots,

(ii) designed to carry safely a load 200 kg (450 lbs.) on the centre of the rung,

(iii) uniformly spaced not exceeding a spacing of 300 mm (12 in.)

(iv) if flat, shall be at least 25 mm (1 in.) by 64 mm (2 ½ in.) and shall be secured by at least three screws or wire nails to each side,

(v) if flat, shall be notched into the side rails at least 13 mm (½ in.) on the lower side, or with fillers installed between the rungs;

(e) has round rungs shall be at least 31 mm (1 1/4 in.) diameter with tenons 6 mm (1/4 in.) less diameter fitting through side rails, secured with a screw or wire nail through tenon at mid-length;

(f) has side rails

(i) dressed on all sides with sharp edges taken off and free from splinters,

(ii) the minimum size of which for single wooden ladders shall be as follows:

Table

| Length of Ladder (feet) | Thickness | Depth |

| Up to and including 20 | 29 mm (1 1/8 in.) | 64 mm (2 ½ in.) |

| Over 20 and up to and including 22 | 31 mm (1 1/4 in.) | 70 mm (2 3/4 in.) |

| Over 22 and up to and including 30 | 31 mm (1 1/4 in.) | 76 mm (3 in.) |

Section 23.5 Step ladders

23.5 (1) The employer shall ensure that

(a) step ladders shall not be over 6 096 mm (20 ft.) in length;

(b) step ladders shall be constructed so that when in the open position of the front section shall have a minimum slope of 89 mm (3 ½ in.) and the back section a minimum slope of 50 mm (2 in.) in each 305 mm (12 in.) length of side rail;

(c) when in position all treads of step ladders shall be level;

(d) the minimum inside width between side rails at the top step of step ladders shall not be less than 305 mm (12 in.) and the side rails shall have an additional spread of 25 mm (1 in.) for each 305 mm (12 in.) of length of step ladder;

(e) step ladders shall be equipped with metal braces to hold legs securely in position;

(f) back legs of all step ladders shall be at least 44 mm (1 3/4 in.) wide and of the same thickness as the side rails;

(g) cross rails and braces of step ladders shall be not less than 13 mm (½ in.) thick and shall be securely fastened;

(h) step ladders 3 048 mm (10 ft.) and less in height shall have a bottom cross rail and diagonal braces;

(i) step ladders over 3 048 mm (10 ft.) in height shall have bottom and intermediate cross rails and two sets of diagonal braces;

(j) cross rails shall not be less than 100 mm (4 in.) wide and diagonal braces shall not be less than 50 mm (2 in.) wide;

(k) step ladders shall be reinforced at each step by a metal tie rod or a metal brace;

(l) metal parts of step ladders shall be of malleable iron, wrought iron or steel;

(m) the material shelf and the top step on a step ladder are clearly marked to indicate that they are not steps.

(2) Side rails of step ladders shall have the following solid cross section or equivalent strength cross section:

Table

| Length of side rail (feet) | Minimum thickness | Minimum width |

| Up to and including 10 | 19 mm (3/4 in.) | 70 mm (2 3/4 in.) |

| Over 10 and up to and including 12 | 19 mm (3/4 in.) | 76 mm (3 in.) |

| Over 12 and up to and including 16 | 19 mm (3/4 in.) | 82 mm (3 1/4 in.) |

| Over 16 and up to and including 20 | 25 mm (1 in.) | 82 mm (3 1/4 in.) |

Note: These thicknesses provide for a gain of not over 1/8 inch in depth. Where gains of a greater depth are required, greater thickness must be used.

Part 29 HAND TOOLS AND PORTABLE POWER TOOLS

Section 29.5 Responsibilities of user

29.5 Without limiting the generality of the duties under section 29.4 every user shall

(a) inspect tools before use;

(b) not use defective tools;

(c) report the existence of defective tools to the employer;

(d) maintain tools in safe working condition;

(e) use tools only for the specific purposes for which they were designed;

(f) place tools in safe suitable containers when not in use;

(g) ensure that tools are not left lying on floors, passageways, stairways or in other places where persons work or are likely to work or pass, or on elevations from which they may fall on persons below;

(h) ensure that sharp edged or sharp pointed tools are provided with protection for the edges or points when not in use;

(i) carry tools in a way that does not interfere with their using both hands on the ladder or while climbing a structure or on any hazardous work requiring the use of both hands;

(j) pass tools from one person to another in a safe manner;

(k) hold with a holding tool or other suitable device all chisels, drills, etc., which are held by one worker and struck by another; and the worker holding the tool shall place himself where he will be in the least danger of being hit by the hammer if it should glance off the tool or if the handle should break;

(l) keep all axes sharp and not use an axe as a mall or wedge;

(m) clear away interfering objects before swinging an axe;

(n) lay crowbars or pinchbars flat in safe places when not in use and not leaning against a flat surface;

(o) keep points or edges of crowbars or pinchbars in good condition to minimize slipping hazards;

(p) keep corrugations on the jaws of pipe wrenches sharp;

(q) use proper size wrenches and spanners when tightening or loosening nuts and bolts;

(r) discard or remove from service till repaired any wrenches with spread, battered or cracked jaws, cracked or broken handles or other defects;

(s) not carry edged or pointed tools such as screwdrivers, chisels, etc., in pocket;

(t) not use pipe or other extensions on wrenches or spanners unless the tools are designed for use in this manner;

(u) not chop towards their feet or legs with an axe.

[EC2021-126, s. 3]

Part 33 POWERED MOBILE EQUIPMENT

Section 33.18 Truck seats

33.18 (1) The employer shall ensure that a truck used for the transportation of workers has seats and is enclosed on all sides.

(2) No person shall get on or off trucks, or be permitted to get on or off trucks, which are in motion.

[EC2021-126, s. 29]

Part 36 ELECTRICITY

Section 36.24 Metal ladders

36.24 The employer shall ensure that metal ladders and ladders having reinforcing wire or other conducting material shall not be used near energized electrical conductors or equipment.

Part 40 TANKS AND VESSELS

Section 40.5 Tank supports

40.5 (1) The supports of all elevated tanks shall be accessible for the purpose of inspection.

(2) Every tank over 1 200 mm (4 ft.) deep containing liquids shall have a fixed permanent cover, and with manholes close to the bottom and need have outside ladders only.

Part 43 HANDLING & STORAGE OF MATERIALS

Section 43.9 Hazardous liquid storage

43.9 The employer shall ensure that tanks used for storing non-flammable hazardous liquids shall meet the following requirements:

(a) labelled to identify the contents and indicate the nature of the hazard involved in handling it as well as instructions for handling of the hazardous liquid;

(b) located above ground or floor level;

(c) so supported that leakage from any part of the tank will be noticeable;

(d) surrounded with pits, catch basins or depressions of sufficient size to hold the entire contents of the largest tank in the event of rupture;

(e) covered with protective paint to prevent corrosion from moisture or fumes; and

(f) provided with stairways or permanent ladders and platforms where necessary, for convenient and safe access to all parts of the tanks with standard safe railings on both stairways and platforms and preferably with floors or platforms constructed of grating.

Section 43.35 Access

43.35 Bins used for storing dry bulk materials shall be provided, on the outside, with stairways or permanent ladders and platforms where necessary for easy and safe access to all parts. Standard railings shall be used on stairways and platforms.